Example 1Adding

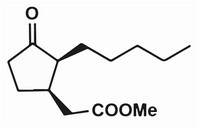

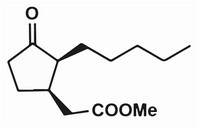

10g of methyl dehydrojasmonate (Compound 1) to a reaction vessel

containing 0.05g of 5wt% Pt/C and 10ml of methanol, substituting with

nitrogen three times, charging 1MPa of hydrogen, stirring at 50 ℃ until

the reaction of the raw materials is completed, and stopping the

reaction. To obtain a reaction solution containing methyl

3-hydroxy-2-pentyl-cyclopentenylacetate (compound 2).And

(3) reducing the reaction temperature of the reaction liquid to 10 ℃,

adjusting the hydrogen pressure to 2MPa, stirring until the raw

materials are reacted, and stopping the reaction. Filtering with celite

pad, adding saturated sodium bicarbonate into the filtrate, extracting,

rectifying under reduced pressure, and separating to obtain colorless

oily cis-3-hydroxy-2-pentyl-cyclopentyl methyl acetate (compound 3)

with yield of 95%. H-NMR (400MHz, CDCl3): 0.89 (t, J =7.0,3H);

1.12-1.20 (m, 1H); 1.22-1.38 (m, 7H); 1.47-1.58 (m, 1H); 1.77-1.83 (m,

2H); 1.91-1.98 (m, 1H); 2.02-2.10 (m, 2H); 2.14 (dd, J =10.0,14.6,1H);

2.38 (dd, J =6.2,14.6,1H); 2.58-2.67 (m, 1H); 3.67 (s, 3H); 3.99 (dt, J

=4.4,6.8,1H).8.0g

of cis-3-hydroxy-2-pentyl-cyclopentylacetic acid methyl ester (compound

3) was dissolved in 10ml of dichloromethane, 0.1wt% of cesium carbonate

was added, the mixture was opened to the atmosphere, the mixture was

stirred at 25 ℃ until the reaction was completed, and the reaction was

stopped after completion of the reaction of the starting materials was

detected. Extraction and reduced pressure distillation are carried out,

thus obtaining the cis-methyl dihydrojasmonate (compound 4) of

colorless oil, the yield is 90 percent, and the cis-isomer content is

92 percent. H-NMR (400MHz, CDCl3): 0.89 (t, J =7.0Hz, 3H); 1.54-1.11

(m, 6H); 1.58 (m, 1H); 1.86 (m, 1H); 2.27-2.07 (m, 5H); 2.30 (q, J

=7.2hz, 1h); 2.42 (dd, J =5.4,15.6hz, 1h); 2.82 (m, 1H); 3.66 (s, 3H).

Example 1Adding

10g of methyl dehydrojasmonate (Compound 1) to a reaction vessel

containing 0.05g of 5wt% Pt/C and 10ml of methanol, substituting with

nitrogen three times, charging 1MPa of hydrogen, stirring at 50 ℃ until

the reaction of the raw materials is completed, and stopping the

reaction. To obtain a reaction solution containing methyl

3-hydroxy-2-pentyl-cyclopentenylacetate (compound 2).And

(3) reducing the reaction temperature of the reaction liquid to 10 ℃,

adjusting the hydrogen pressure to 2MPa, stirring until the raw

materials are reacted, and stopping the reaction. Filtering with celite

pad, adding saturated sodium bicarbonate into the filtrate, extracting,

rectifying under reduced pressure, and separating to obtain colorless

oily cis-3-hydroxy-2-pentyl-cyclopentyl methyl acetate (compound 3)

with yield of 95%. H-NMR (400MHz, CDCl3): 0.89 (t, J =7.0,3H);

1.12-1.20 (m, 1H); 1.22-1.38 (m, 7H); 1.47-1.58 (m, 1H); 1.77-1.83 (m,

2H); 1.91-1.98 (m, 1H); 2.02-2.10 (m, 2H); 2.14 (dd, J =10.0,14.6,1H);

2.38 (dd, J =6.2,14.6,1H); 2.58-2.67 (m, 1H); 3.67 (s, 3H); 3.99 (dt, J

=4.4,6.8,1H).8.0g

of cis-3-hydroxy-2-pentyl-cyclopentylacetic acid methyl ester (compound

3) was dissolved in 10ml of dichloromethane, 0.1wt% of cesium carbonate

was added, the mixture was opened to the atmosphere, the mixture was

stirred at 25 ℃ until the reaction was completed, and the reaction was

stopped after completion of the reaction of the starting materials was

detected. Extraction and reduced pressure distillation are carried out,

thus obtaining the cis-methyl dihydrojasmonate (compound 4) of

colorless oil, the yield is 90 percent, and the cis-isomer content is

92 percent. H-NMR (400MHz, CDCl3): 0.89 (t, J =7.0Hz, 3H); 1.54-1.11

(m, 6H); 1.58 (m, 1H); 1.86 (m, 1H); 2.27-2.07 (m, 5H); 2.30 (q, J

=7.2hz, 1h); 2.42 (dd, J =5.4,15.6hz, 1h); 2.82 (m, 1H); 3.66 (s, 3H).

Publication number

Priority date

Publication date

Assignee

Title

JPH0665151A

*

1992-08-25

1994-03-08

Japan Tobacco Inc

Production of dihydroepijasmic acid methyl ester

WO2004108652A2

*

2003-06-06

2004-12-16

Universita' Degli Studi Di Pavia

Enantioselective process for the preparation of methyl dihydroepijasmonate

CN100999466A

*

2006-01-11

2007-07-18

浙江新和成股份有限公司

Synthesizing process of cis-dihydro jasmine keto-acid methyl ester

CN101475480A

*

2008-12-11

2009-07-08

淮安万邦香料工业有限公司

Method for synthesizing cis-methyl dihydrojasmonate

CN101613277A

*

2009-07-30

2009-12-30

淮阴师范学院

Improve the method for content of cis-methyl-dihydrojasmonate

CN101914000A

*

2010-08-18

2010-12-15

北京航空航天大学

Method for preparing aldehyde or ketone by non-catalytic reaction

CN108863787A

*

2017-05-12

2018-11-23

南开大学

3- alkyl

-2- carbethoxyl group substituted cyclic is conjugated asymmetric

catalytic hydrogenation and its application of ketenes

CN109384675A

*

2017-08-14

2019-02-26

南开大学

The Enantioselective total synthesis method of needle juniper celery alkane type diterpene and the like

**********************************************************************************************************

Method for preparing methyl dihydrojasmonate CN

CN101519355B 胡雨来 西北师范大学

Priority 2009-03-17 • Filed 2009-03-17 • Granted 2011-11-30 • Published 2011-11-30

Abstract

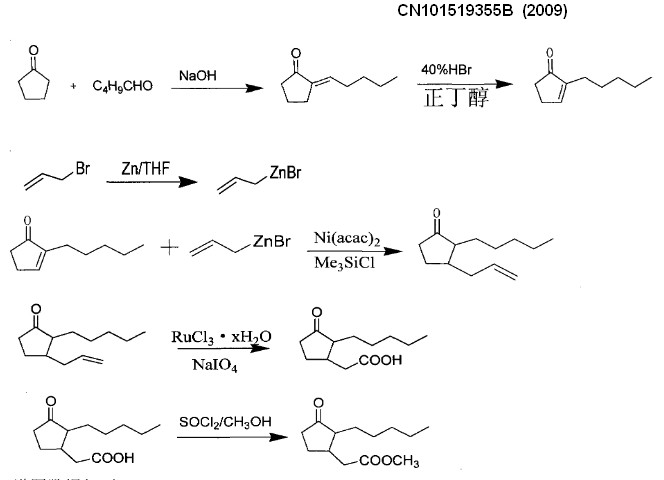

The

invention provides a method for synthesizing methyl dihydrojasmonate.

2-pentyl cyclopentenone is adopted as a raw material; the raw material

and allyl zinc bromide are subjected to 1,4-Michael addition to form

2-pentyl-3-allyl cyclopentanone; the 2-pentyl-3-allyl cyclopentanone is

oxidized by sodium periodate in the presence of a ruthenium trichloride

hexahydrate catalyst to synthesize dihydrojasmonic acid; and then the

dihydrojasmonic acid is esterified to form the methyl dihydrojasmonate.

The raw material of the method is cheap and low in cost; the process is

simple and convenient in operation; the reaction conditions are mild

and easy to control; the synthesis route is short and the synthesis

period is reduced greatly; and the reaction product is single, high in

yield (up to 65 to 85 percent), less in environmental pollution, and

environmentally-friendly.

Embodiment

The present invention is described further below by concrete enforcement.

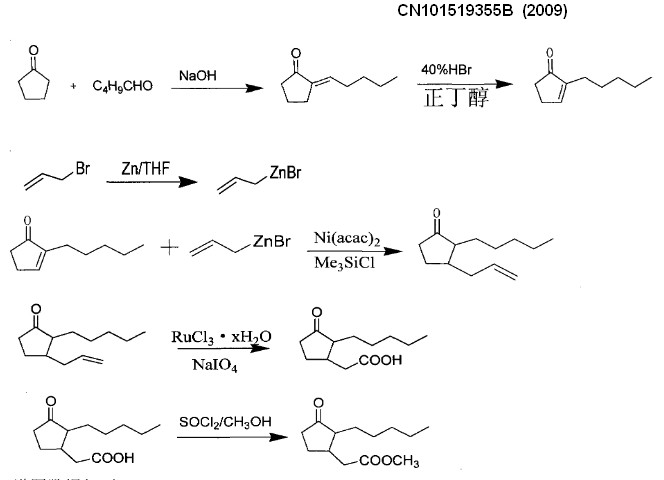

Step 1:

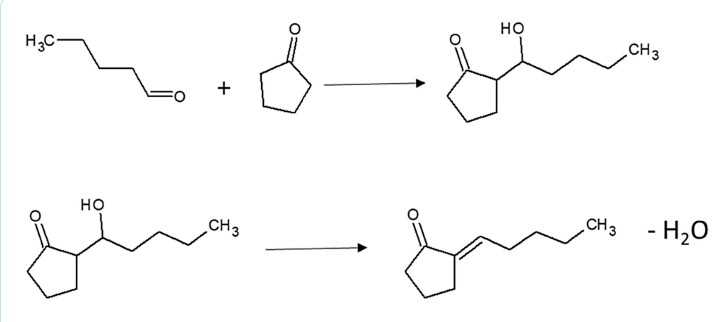

the preparation of 2-amyl cyclopentenoneThe 2-amyl cyclopentenone can be bought from the market, also can get by following prepared:

With

NaOH (0.83g), H 2O (75ml) adds there-necked flask, is heated to 25 ℃

with water-bath, drips cyclopentanone (38g) from dropping funnel, keeps

temperature of reaction to be no more than 32 ℃ during dropping, drips

valeraldehyde (22g) after adding again, keeps reacting liquid

temperature to be no more than 32 ℃.Add the back at 28 ℃ of reaction

1h, add acetate (1.5g) and stir 2min, tell organic layer, once with the

saturated common salt washing.

Add NaHSO 4Solution at room

temperature stirs 20min, adds a small amount of propyl carbinol.Tell

organic layer, wash once with saturated common salt aqueous

solution.Organic layer is put into round-bottomed flask, add the HBr

(6.5ml) of propyl carbinol (132ml) and 40%, behind the reflux 1.5h,,

pour separating funnel into, use saturated NaCl, NaHCO successively the

reaction solution cooling 3, the NaCl solution washing, the anhydrous

MgSO of organic layer 4Dry.With water pump pressure reducing and

steaming propyl carbinol, use the oil pump underpressure distillation

again.Collect 130 ℃~140 ℃, the cut of 0.085MPa gets colourless liquid,

is the 2-amyl cyclopentenone.Productive rate 65%.Its reaction formula

is as follows:

Figure G2009100218015D00031

The spectral data of product characterizes as follows:

IR(KBr)v maxcm -1:2926,2858,1704,1633;

1HNMR(400MHz,CDCl 3):δ=0.83-0.90(m,3H),1.25-2.58(m,12H),7.29-7.31(m,1H);

13CNMR(100Hz,CDCl 3):δ=210.1,157.3,146.5,34.5,31.5,27.4,26.4,22.4,13.9。

Step 2:

the preparation of 2-amyl group-3-allyl group cyclopentanone(1) preparation of allyl group bromination zincon

Allyl group bromination zincon can be bought from the market, also can get by following prepared:

In

exsiccant two neck bottles (50ml), put into zinc powder (0.021mol),,

add tetrahydrofuran (THF) (THF) (3ml) with 1 with the air in the

nitrogen replacement bottle, 2-ethylene dibromide (4~5), the reaction

mixture heating up to there being bubble to produce, is naturally

cooled to room temperature, add trimethylchlorosilane (Me 3SiCl) (4~5),

stirring at room 15min adds allyl bromide 98 (0.020mol) and

tetrahydrofuran (THF) (THF) (10ml) then, and stirring reaction is

standby.Its reaction formula is as follows:

Figure G2009100218015D00041

(2)

under nitrogen protection, in another 100ml three-necked bottle, put

into acetylacetonate nickel (Ni (acac) 2) (0.0012mol), triethylamine

(Et 3N) or triphenyl phosphorus (Ph 3P) (0.0048mol), tetrahydrofuran

(THF) (THF) (10ml) is heated to reaction mixture 60 ℃, and stirring

reaction 10min is cooled to room temperature, slowly adds the allyl

group bromination zincon of above-mentioned preparation, after adding

reaction mixture is chilled to-15 ℃ with the cryosel bath.From dropping

funnel, drip 2-amyl cyclopentenone (0.010mol), trimethylchlorosilane

(Me then 3SiCl) (0.018mol) and the mixture (5ml) formed of

tetrahydrofuran (THF) (THF).Add the back and continue stirring

reaction, allow cryosel bathe nature and be warming up to room

temperature, coreaction 12 hours.The 5mol/L HCl that in reaction flask,

adds 10ml then, restir reaction 1 hour.Add the 10ml ether, organic

phase is told in extraction.Use anhydrous magnesium sulfate drying,

residuum carried out column chromatography after boiling off solvent,

colourless or light yellow liquid, be 2-amyl group-3-allyl group

cyclopentanone.Productive rate 73%.Its reaction formula is as follows:

The spectral data of product characterizes as follows:

IR(KBr)v maxcm -1:2927,2858,1740,1641;

1HNMR(400MHz,CDCl 3):δ=0.87(t,J=7.0Hz,3H),1.26-2.43(m,16H),5.05-5.10(m,1H),5.77-5.79(m,1H),5.81-5.88(m,1H);

13CNMR(100Hz,CDCl 3):δ=221.1,135.8,116.6,54.2,41.1,38.6,37.7,32.1,28.0,26.5,26.4,22.4,14.0。

S

tep 3: the preparation of Dihydrojasmone acidIn

the 50ml round-bottomed flask, add 0.388g 2-amyl group-3-allyl group

cyclopentenone, add 7ml water and 7ml acetonitrile again, add the 1g

sodium periodate then, stir, add the 0.02g hydrate ruthenium

trichloride again, the temperature of solution rises to 30 ℃ gradually,

keep temperature of charge under 12 ℃~20 ℃, slowly add the 3.5g sodium

periodate, reactant was stirred 2 hours down at 17 ℃, added the ethyl

acetate stirring reaction then 1 hour, filter, filtrate is used

saturated Na then with 0.1mol/L salt acid elution 2S 2O 3Solution

washing is used ethyl acetate extraction, collected organic layer, and

solvent evaporated gets yellow pasty state liquid, and column

chromatography gets colourless liquid, is Dihydrojasmone

acid.Productive rate 92%.Its reaction formula is as follows:

Figure G2009100218015D00051

The production spectra diagram data characterizes as follows:

IR(KBr)v maxcm -1:2924,2854,1739,1710,1459;

1HNMR(400MHz,CDCl 3):δ=0.88(t,J=7.2Hz,3H),1.23-2.68(m,16H),11.18(s,1H);

13CNMR(100Hz,CDCl 3):δ=219.6,178.1,54.1,38.7,37.7,37.6,32.0,27.7,27.1,26.2,22.4,14.0。

Step 4: the preparation of methyl dihydrojasmonate0.55g

methyl dihydrojasmonate and anhydrous methanol (20ml) are joined in the

three-necked bottle, slowly drip thionyl chloride (SOCl down at 0~-15 ℃

2) (1.5ml), stirring reaction recession in 1 hour deicing salt bath at

room temperature continues to stir after 3~5 hours, boils off anhydrous

methanol on Rotary Evaporators, obtains the target product methyl

dihydrojasmonate.Productive rate 84%, its reaction formula is as

follows:

The production spectra diagram data is as follows:

IR(KBr)v maxcm -1:2955,2930,2859,1739,1437,1166;

1HNMR(400MHz,CDCl 3):δ=0.87(t,J=7.0Hz,3H),1.22-2.65(m,16H),3.71(s,1H);

13CNMR(100Hz,CDCl 3):δ=

219.7,172.6,54.1,51.6,38.9,38.0,37.7,32.0,27.8,27.2,26.3,22.4,14.0。

Use other catalyzer, lewis acidic embodiment same as the previously described embodiments.

*******************************************************************************

Bio-based methyl dihydrojasmonate, bio-based cyclopentanone, preparation method …

WO CN

CN118871415A 阎震 法国特种经营公司

Priority 2022-01-31 • Filed 2023-01-31 • Published 2024-10-29 (Rhodia patent)

The

invention relates to biobased methyl dihydrojasmonate, biobased

cyclopentanone, a preparation method and application thereof.

Background

Methyl

dihydrojasmonate (CAS 24851-98-7) is an aromatic compound, the odor of

which is floral and citrus when in the form of a racemic mixture. The

compounds are used in the perfume industry and the food industry.

Methyl dihydrojasmonate is used as a synthetic equivalent of methyl

jasmonate, a component of naturally occurring jasmine. Industrially,

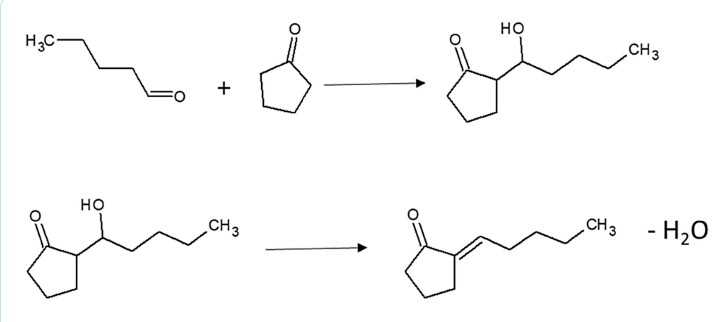

methyl dihydrojasmonate can be prepared from adipic acid as a precursor

for the preparation of cyclopentanone. Cyclopentanone can then be

functionalized by aldol condensation with valeraldehyde followed by

michael addition of dimethyl malonate.

Synthetic flavors are less

preferred by consumers than natural-derived flavors. Thus, there is

increasing interest in other sources of methyl dihydrojasmonate, and in

particular in ways that use natural raw materials that can be marked as

natural or biological in accordance with existing regulations.

E

xamplesExample 1: preparation of biobased cyclopentanone3G

of biobased furfuryl alcohol (100% biobased carbon content) was

hydrogenated in 60mL of water in the presence of a nickel catalyst (30

mg). The hydrogen pressure was 30 bar and the temperature was 160 ℃.After

stirring for 3-4 hours, the reaction mixture was analyzed. Biobased

cyclopentanone was obtained and showed a biobased carbon content of

100%. The conversion rate is 100%.Example 2: preparation of methyl biobased dihydrojasmonate.The

biobased cyclopentanone of example 1 (100% biobased carbon content) was

reacted with valeraldehyde to produce the compound of formula (III).The compound of formula (III) is then reacted with 100% dimethyl biobased malonate having a 100% biobased carbon content.Methyl dihydrojasmonate was obtained and showed a biobased carbon content of 62%.

Publication number

Priority date

Publication date

Assignee

Title

CH382731A

1960-02-25

1964-10-15

Firmenich & Cie

Process for the preparation of alicyclic keto esters

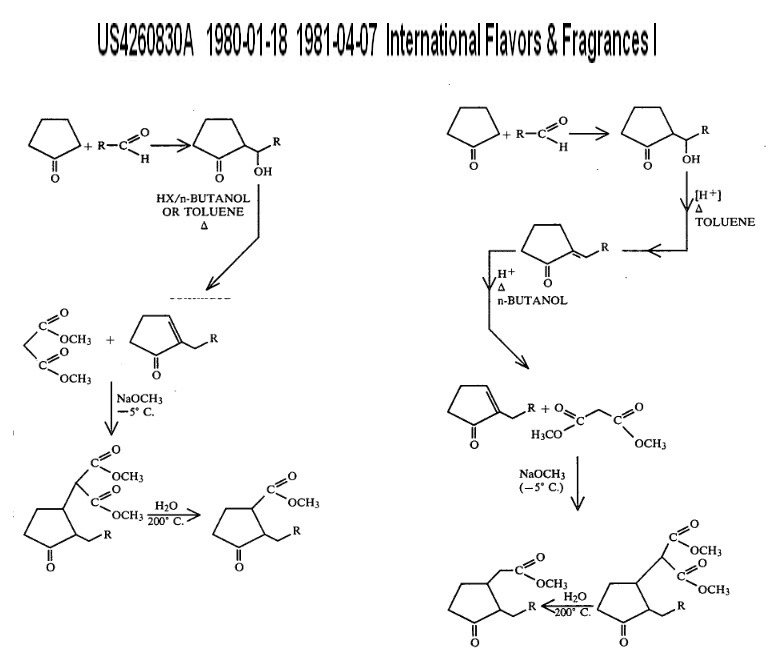

US4260830A

1980-01-18

1981-04-07

International Flavors & Fragrances Inc.

Process for the preparation of methyl dihydrojasmonate and lower alkyl homologues

DE69031954T2

*

1989-05-23

1998-09-03

Nippon Zeon Co

Fragrance composition

KR101078629B1

*

2005-06-30

2011-11-01

아사히 가세이 케미칼즈 가부시키가이샤

Process for production of substituted cyclopentanone

CN105330523A

*

2015-10-22

2016-02-17

复旦大学

Method for preparing cyclopentanone by taking biomass resource as raw material

CN108863738B

*

2017-05-08

2021-09-07

万华化学集团股份有限公司

Method for preparing cyclopentanone

CN108380206B

*

2018-02-22

2021-04-20

万华化学集团股份有限公司

Method for preparing cyclopentanone through furfuryl alcohol rearrangement hydrogenation

EP4022056A4

2019-08-30

2024-07-03

Lygos Inc

Recombinant host cells for the production of malonate

CN112194577A

*

2020-09-03

2021-01-08

大连理工大学

Method

for preparing cyclopentanone compounds from furfural and furfural

derivatives through aqueous phase hydrogenation rearrangement

* Cited by examiner, † Cited by third party

********************************************************a exploer

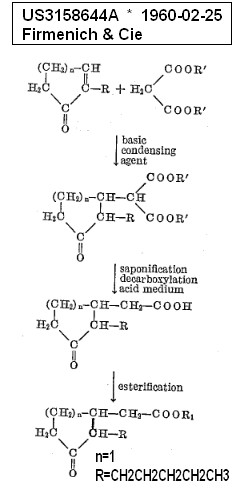

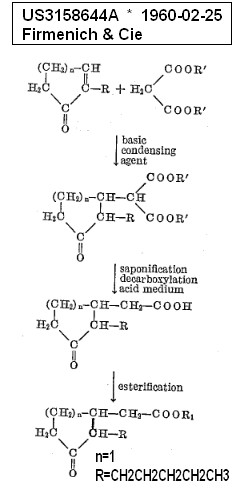

CH382731A 1960-02-25 1964-10-15 Firmenich &

Cie Process for the preparation of alicyclic keto

esters starting patent for methyldihydrojasmonate FR US3158644A

* 1960-02-25 1964-11-24 Firmenich & Cie

Alicyclic ketoesters and process for their manufacture

**********************************************************

aldol condensation cyclo +valeraldehyde

info here

*******************************************************************

US-3978108-A

Cis methyl dihydrojasmonate S.A. Des Etablissements

Roure-Bertrand Fils & Justin Dupont

1970-12-23

Cis methyl dihydrojasmonate

Abstract

Methyl

dihydrojasmonate containing a major proportion of cis methyl

dihydrojasmonate. The NMR spectrum of cis methyl dihydrojasmonate is

illustrated in the attached drawings.Cis methyl dihydrojasmonate

displays olfactory properties superior to those of the trans isomer

making it very useful as an odoriferous agent. In order to prepare

methyl dihydrojasmonate containing a major proportion and preferably at

least 90% of cis isomer, methyl

(2-pentyl-3-keto-cyclopenten-1-yl)-acetate is catalytically

hydrogenated in the presence of an aluminium derivative

The preparation of methyl

dihydrojasmonate, the chemical name of which is methyl

(2-pentyl-3-keto-cyclopentyl)-acetate, is described in as well as in

French Pat. No. 1,280,432 U.S. Pat. No. 3,158,644.

While methyl dihydrojasmonate is capable of existing in both the trans

and cis forms, and is so generally indicated, for instance, in said

U.S. patent, the face is that the cis form has not heretofore been

isolated nor characterized. Furthermore, the process disclosed in said

patents, production of either 100% of the trans isomer or possibly a

very small percentage at best of the cis isomer intermingled with the

essentially overwhelming content of the trans isomer, the latter

constituting no less than about 95% by weight, perhaps more, of the

methyl dihydrojasmonate. These two forms can be represented, in

accordance with the usual conventions, by formulae I and II

respectively. ##SPC1##

A process has now been found which

enables the production of methyl dihydrojasmonate containing a major

proportion, that is, more than 50% by weight, of the cis isomer. The

process of this invention has proved to be capable of giving a methyl

dihydrojasmonate containing upwards of 90% of the cis isomer.

It has

furthermore surprisingly been found that cis methyl dihydrojasmonate

and also methyl dihydrojasmonate containing a major proportion of the

cis isomer is distinguished from the earlier trans product both by its

olfactory characteristics and in that the physicochemical properties of

the cis isomer differ from those of the trans isomer.

Publication number

Priority date

Publication date

Assignee

Title

US3158644A

*

1960-02-25

1964-11-24

Firmenich & Cie

Alicyclic ketoesters and process for their manufacture

DE2008878A1

*

1969-03-10

1970-09-24

L. Givaudan & Cie S.A., Vernier-Genf (Schweiz)

New cycloalkenone esters

GB1206981A

*

1967-10-13

1970-09-30

Toray Industries

Method of activating raney alloys

FR1280432A

*

1961-02-17

1961-12-29

Firmenich & Cie

Alicyclic ketoesters and process for their preparation

****************************************************************************************

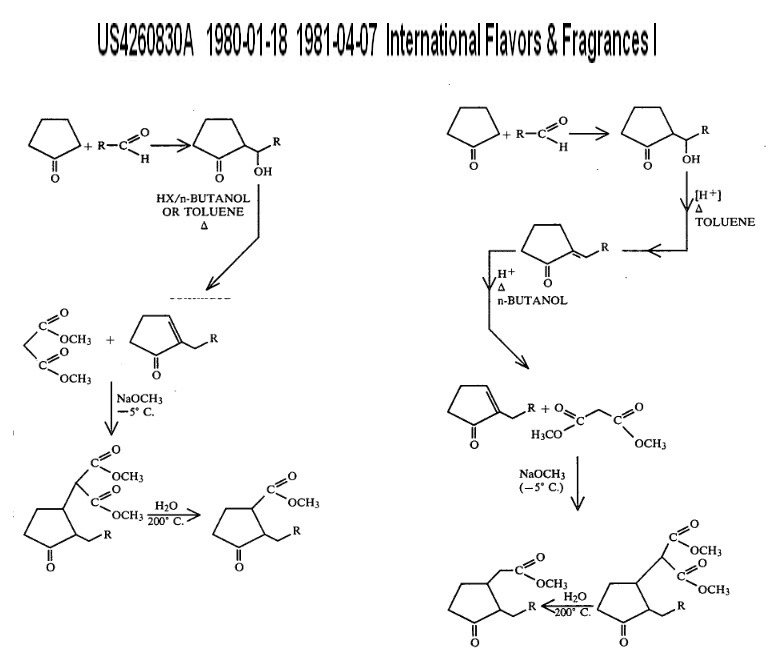

US4260830A

1980-01-18

1981-04-07

International Flavors & Fragrances Inc.

Process for the preparation of methyl dihydrojasmonate and lower alkyl homologues

full details here

full details here

****************************************************************************************

more patent litterature references

full details here

full details here